By Charlie Stevens

It seems that each year, contractors are asked to deliver projects faster and faster. In the recent recession, owners demanded it and contractors accepted it and were thankful to have a project. Now, even though there is more work in the marketplace, owners" demands have not changed. Remarkably fast construction schedules that previously seemed like the exception have become the norm.

It seems that each year, contractors are asked to deliver projects faster and faster. In the recent recession, owners demanded it and contractors accepted it and were thankful to have a project. Now, even though there is more work in the marketplace, owners" demands have not changed. Remarkably fast construction schedules that previously seemed like the exception have become the norm.

Superintendents have the responsibility to meet the owner's schedule requirements and deliver the project when promised. In order to meet the overall schedule, one of the most critical activities is to manage the work crew's daily performance. As with cost — “if you watch the pennies, the dollars take care of themselves,” so with schedules — “if you watch the days, the months take care of themselves.”

Without creating useful tools, how can we successfully manage performance trends? One way to do this is by analyzing performance trends.

It is imperative for today's superintendents to know the project status relative to schedule at all times. The success of a project schedule is determined early on by maintaining positive performance trends. Failure to recognize a negative performance trend early in the process can be devastating to the overall project and create a situation in which the team can never recover.

In order to recognize both positive and negative trends, the project team must first establish performance criteria and measure it daily against the allotted time in the project schedule. The unit of measure can be pieces erected, square footage, lineal footage, cubic footage, cubic yards, etc., of the activity or material to be installed, divided by the time, days, weeks, hours, etc.

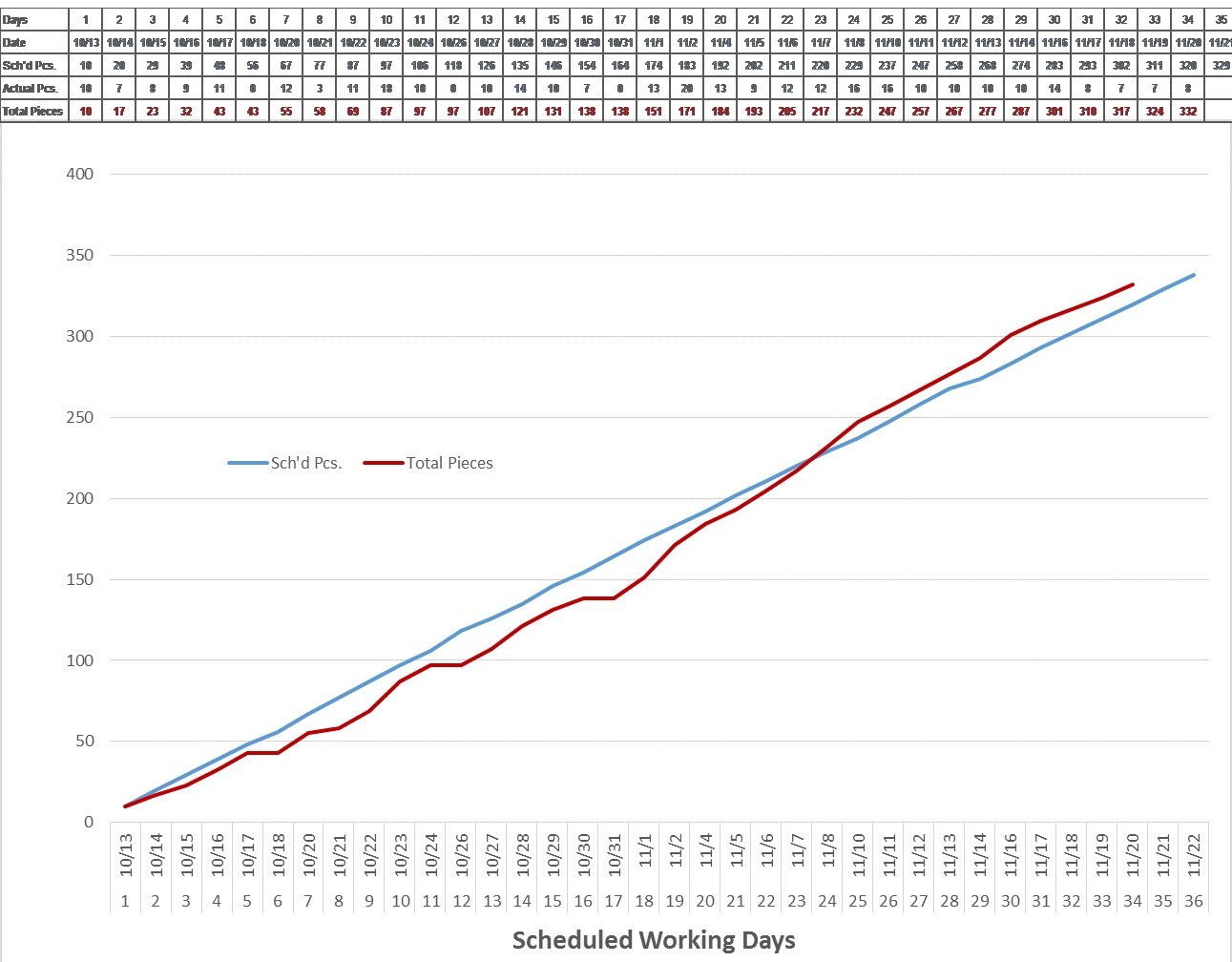

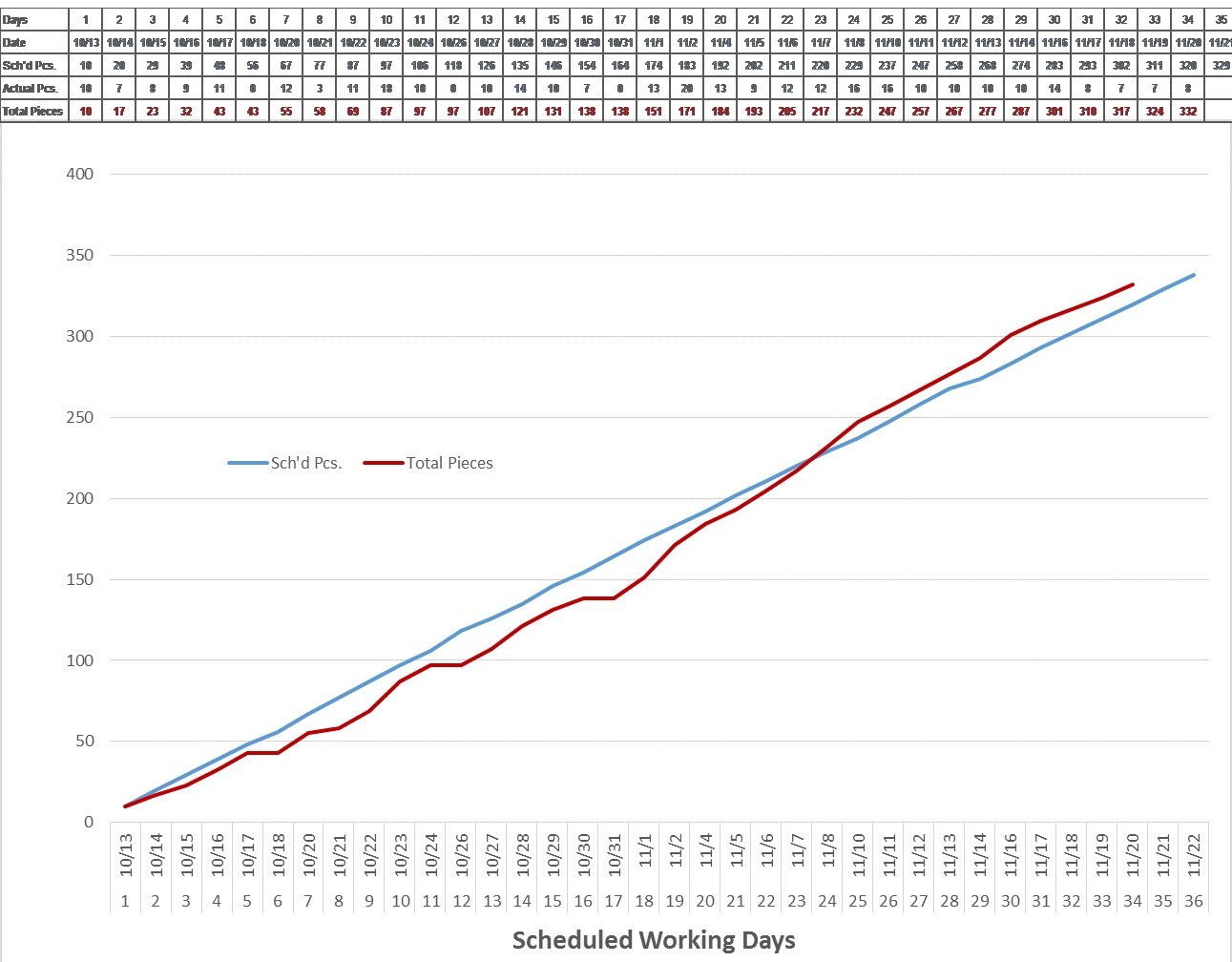

Documenting work completed can be simply depicted graphically by noting on a PDF drawing, or within the BIM model, the planned work for each day or week and updating the drawing or model frequently, noting the amount completed. While this method communicates to the team what has been done, it does not provide information on trends or where the project may be heading. A simple way to track actual performance against planned performance and predict trends is the use of a spreadsheet for data entry and graphing the information collected for easy visualization, such as in the example below.

Example: If we have 1,000 units to complete in 100 days, the average daily productivity should be 10 units, or 1.25 units per hour for an eight hour day. At day 20, we should have 200 units completed. If we only have 180 units completed and are behind on daily productivity, we must make adjustments and work to reverse the negative trend. We have 82 percent of the task left to complete, with only 80 percent of the time available, per the original schedule. In addition, the hourly productivity realized is 10 percent less than planned productivity.

Managing a negative trend

The first step in managing a negative trend is to recognize the resources available. Depending on the task to be completed, there may be a need to develop an approach to work more efficiently, work additional hours, or increase labor. In the example presented above, with 82 percent of the task left to complete in only 80 percent of the time, superintendents would need to determine an installation method that allows the labor force to install more units in a given day, or if the productivity cannot be improved, either shift to a 10-hour day with the current crew, or increase the labor staff to accomplish more work in the normal workday.

To successfully manage and monitor daily performance, it is imperative to fully understand the task with enough detail to identify when a negative trend is starting and be able to reverse negative trends when they occur. Furthermore, fully understanding the task and what is to be measured is necessary for selecting the most appropriate measurement tool — whether an Excel spreadsheet, balanced scorecard, worker performance index or an advanced software model.

The success of any project is dependent on time management. It is critical to monitor trends and use tools to track daily performance. Displaying graphical reports of both work completed and predicted completion based on historical trends are excellent tools when discussing performance issues with work crews or subcontractors.

With detailed and accurate information, guessing and gut feeling are not part of the discussion, and these discussions are held when there is still time for recovery. Recognizing a negative trend too late into a project is one ingredient in the recipe for project failure— and no one wants to be part of a failed project.

Charlie Stevens is vice president and construction manager at The Austin Company.

Join our thriving community of 70,000+ superintendents and trade professionals on LinkedIn!

Join our thriving community of 70,000+ superintendents and trade professionals on LinkedIn! Search our job board for your next opportunity, or post an opening within your company.

Search our job board for your next opportunity, or post an opening within your company. Subscribe to our monthly

Construction Superintendent eNewsletter and stay current.

Subscribe to our monthly

Construction Superintendent eNewsletter and stay current.