By Rachael Farr

Construction containment methods are an important part of every type of construction, but are especially critical when performing addition or renovation work at healthcare facilities. In both instances, construction often occurs on active patient floors, within units or just feet away from patient rooms. No matter the scenario, the most important aspects of the work lie in the planning and communication of what is to come.

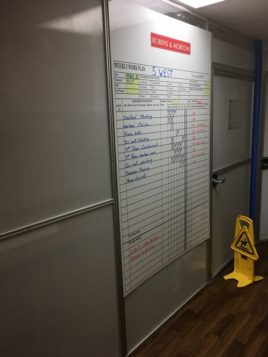

On interior renovation projects, project teams can place communication boards on the outside of the construction barriers as a proactive measure with healthcare facility staff.From the outset of the project, the construction team considers the best way, from a constructability standpoint, to approach regulations, phasing, material delivery, workforce routing, interim life safety measures and what kind of barriers are right for the project. Once the constructability recommendations are decided, Robins & Morton Superintendent Jeff Jones says getting hospital staff [owner] buy-in is key.

“How you get [material] and workers in and out of the space affects the staff,” Jones said. “Getting their input, especially in establishing the phasing plans, helps us to better meet their needs.”

Once the phasing plan has been established, Robins & Morton Superintendent JT Coleman says the next important meeting is with the designers.

“Once you learn the regulations for the area, it’s important to meet with the design team,” Coleman said. “I ask them to put all the planned barriers, temporary signage, interim life safety measures and egress on the drawings.”

Starting point: Early communication

This early communication among all parties participating in the construction process helps in the early stages of kicking off the project, but both Coleman and Jones said that it can’t stop there.

At Jones’ current project, Beverly Knight Olson Children’s Hospital Navicent Health in Macon, Georgia, he and his team meet with the nurses that work at the addition’s tie-in point every Monday. In that meeting, they discuss the week’s upcoming work and address the level of noise that may occur in some of the planned activities. Jones said that by sharing this information, the staff can inform him and his team if there is a coordination issue, or an extenuating circumstance that would require them to move an activity.

The hospital staff at Coleman’s current project, Florida Hospital Carrollwood in Carrollwood, Florida, utilizes certain Lean tools, like daily stand-ups — meetings where tasks and constraints are discussed. While Coleman’s team worked inside the hospital, they participated in the staff’s meetings providing updates and discussing any impending issues every day. Now that Coleman’s team works primarily on the outside of the building, they maintain weekly touchpoints with the staff.

Each project also utilizes various visual tools to communicate the project’s progress like information boards outside project barriers and weekly A3s – 11-by-17 placemat-style progress reports for owner, architect and contractor meetings. Each proactive step leads to more open communication among construction and hospital personnel, which leads to better risk management, Jones said.

Rising trend: Intermediate barriers

Aside from the procedure-driven aspects of the project, there is one major trend catching across many healthcare projects: intermediate barriers. In years past, there have been traditional “hard wall barriers,” also known as temporary walls, that keep a construction project away from active hospital floors by essentially installing metal studs and drywall that will be later demolished to open the space, or soft barriers — a series of connected plastic sheets, enterable by a zipper doorway.

While there is no substitute for an actual wall, JJ Jenkins, owner of Jenkins Risk Management and founder of the Construction Infection Control Training Institute, says that intermediate barriers are beginning to take the place of many soft barriers. Intermediate barriers are often characterized by interlocking panels raised and fastened to the ceiling grid, with doors in the panels to isolate potentially harmful dust. Many companies sell these interlocking barriers, however Jenkins has also seen several companies fabricating their own onsite with lightweight metal studs and chloroplast.

Despite the convenience, some balk at the initial sticker price of the intermediate barrier paneling system versus polyethylene plastic barriers, but Jenkins said the paneling systems can be cleaned and reused over a short period of time. A contractor would actually spend more on plastic barriers.

Addressing non-compliance in infection control

In addition to not being cost-effective or environmentally sustainable, the failure of plastic barriers is one of the top non-compliance issues in infection control. Because of the need to use negative air pressure on the jobsite, barriers also need designated makeup air.

While the panel system accomplishes this with a designated opening that may be covered with a filter allowing air to enter the barriers and preventing dust from escaping, there is no real option to acquire the needed makeup air in a plastic barrier without putting a hole in it, which is an at-risk behavior. Because of the lack of makeup air in that scenario, plastic barriers are likely to collapse on themselves, exposing the area to harmful dust and particles.

Jenkins said that while time and money will always be a consideration, planning-based solutions are key.

For example, planning for ante-rooms — spaces between the active hospital and construction that allow people and material to enter the jobsite without exposing the healthcare facility to construction dust.

“Often, ante-rooms are made too small to accomplish the objectives of the ante-room,” Jenkins said. “But if your ante-room isn’t large enough to accommodate people and associated materials, it can’t do its job.”

Careful planning

Jenkins said the solution to this is to plan the area carefully and know there may be a need to revise the flow of some flooring and above-ceiling work as a result.

Another challenge, Jenkins sees, comes with rigid barrier placement. While rigid barriers are a superior solution to polyethylene sheets, some barrier placement can negatively affect important hospital operations.

“Sometimes barrier placement can impact operational traffic flow and trauma routes,” Jenkins said. “For example, they can create choke points or increase travel time in emergent situations.”

By being cognizant of how construction barriers may change the landscape of an existing corridor and ensuring the barrier’s corresponding door swings inward instead of outward, contractors can mitigate operational impacts where the hospital and jobsite merges.

“[To avoid these risks] it’s imperative that people get proper training as it relates to infection control containment and procedure,” Jenkins said.

Jones and Coleman both echo that sentiment when working to protect the patients, staff and their family members on their own projects.

“We just think about how we want people to act around our families. We have to remember it can be life or death,” Jones said. “We have to treat it that way, understanding risk, checking and double checking to protect people that are already sick.”

To best problem solve and ensure the risk is not there, Coleman knows that working with hospital staff and ensuring they are pleased with the plans made is the only way to conduct a successful project, from barrier choice to order of phasing.

“[Starting construction] inside a hospital is like someone moving into your house for a short amount of time, and saying, ‘hey, I’m going to build a wall here,’” Coleman said. “Our goal is to keep them informed, onboard and satisfied.”

Rachael Farr is communications coordinator at Robins & Morton.

Join our thriving community of 70,000+ superintendents and trade professionals on LinkedIn!

Join our thriving community of 70,000+ superintendents and trade professionals on LinkedIn! Search our job board for your next opportunity, or post an opening within your company.

Search our job board for your next opportunity, or post an opening within your company. Subscribe to our monthly

Construction Superintendent eNewsletter and stay current.

Subscribe to our monthly

Construction Superintendent eNewsletter and stay current.