By Dan Ruane

Even as the Occupational Safety and Health Administration demands a high standard, construction safety continues to be an area of opportunity for the industry. As the U.S. Bureau of Labor Statistics reports 1,008 fatalities in 2020, there remains a compelling need for improvement.

All workers have the right to a safe work environment, and jobsite safety should always be a top priority for any construction company. Beyond the moral obligation, it makes financial sense. A U.S. National Safety Council survey reveals that each dollar invested in safety measures returns $2 in avoided costs.

The challenge: traditionally, safety trainings are one-way conversations. Team members receive job-specific training each time they start on a new jobsite, which means they are often subject to hearing the same presentations multiple times. This promotes a different kind of hazard: tuning out – a significant vulnerability with high potential for injuries.

A single question can lead to a decisive moment for the industry: how to turn general safety training monologues into constructive dialogues to create experiences people remember?

Virtual training, real hazards

So much of safety awareness is based on situational context. Reading about a situation, or hearing an instructor’s description is informative, but what happens when team members can physically immerse themselves in a replicated jobsite with real hazards? They learn to recognize and effectively address these before they even set foot on the site.

Real-life experience is the best kind of training. Creating a fully immersive training solution doesn’t have to involve extensive investment. Custom solutions can come by leveraging in-house tools and resources like virtual reality. It’s the closest the industry can come to safely engaging teams in authentic learning environments, replicating unsafe situations without actually exposing individuals to real risk.

When combined with gaming software, this virtual tool, commonly used to help clients understand how new spaces will function and flow before they are built, can be a game changer for safety training. In fact, studies show that VR training significantly improves retention, test scores and empathy, which indicates people are more likely to consider their own safety, as well as that of coworkers after completing a VR training session.

Lessons in vertical concrete

Industry-wide, concrete work tends to have a higher rate of incidents and injuries. Of particular concern are high-severity and high-frequency of injuries that come with fall protection and material handling.

Today’s technology makes it easier to generate a virtual representation of real-life conditions. Using technology to help with safety, Pepper implemented VR safety training performing the concrete work on Riverline towers, a mix of town- and sky-homes, apartments and condominiums located at 720 South Wells in Chicago, Illinois’ South Loop neighborhood.

A 3D scan of the existing conditions, populated with virtual objects, can represent a potential risk-laden scenario. With a Point Cloud Scan of the Riverline Towers project, materials that could be potential hazards, such as concrete buckets and dumpsters, were placed on an existing pre-pour concrete laser scan and then imported into the modeling tool, 3ds Max. Even non-experts can turn the modelling of a scenario into a unique VR training opportunity using a creation engine like Unreal Engine. Since many projects start with a BIM model these days, the platform data often already exists to move the model to VR.

With input from team members who will utilize the training, programs can be created to match the most common real-life hazards on jobsites. In-house creation also allows flexibility for quick pivoting to make changes as data evolves and trends emerge.

Self-Perform Group Superintendent Chris Hrnciar worked on the Riverline Towers project. Speaking about his training, he says, “It really was like a real jobsite. There were people working above you in the core. You really had a thousand things all over the place that you could trip over, the cables, the stub-ups. It’s surprisingly realistic.”

Concrete outcomes

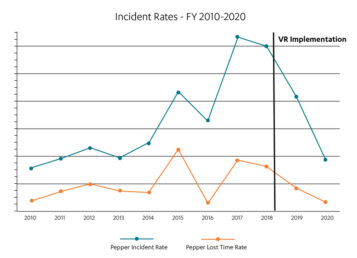

Shared with field leaders, the virtual reality module got some really great feedback. While many elements, such as increased attention and awareness, contribute to improved safety, qualitative feedback from participants shows an undeniable connection between the VR safety-training program and a reduction in incidents at the jobsite.

The goal is engagement and retention. To expand accessibility, Pepper regularly brings new hires into the office for VR safety training as part of the safety orientation program.

There is nothing proprietary about good safety practices. “We’ve had opportunities to share this training program with industry peers through conference presentations and trade publications,” says Jennifer Suerth, vice president of technical services. “Our efforts have recently been recognized with the top 2021 Innovation Award from the Associated General Contractors of America. Based on the positive reviews from both internal and external audiences, we’re now focusing on a drywall safety session using the same approach.”

Award-winning is commendable. Impact on safety, quality, bottom line and schedules of projects is tangible. The real win – making tradespeople safer on projects and knowing that safety across the construction industry will feel the positive impact, as they carry their learning with them to more jobsites.

To learn more about Pepper Construction’s virtual safety program, visit https://www.pepperconstruction.com/blog/making-vr-safety-training-reality, and at https://www.pepperconstruction.com/videos/virtual-reality-safety-training.

Dan Ruane is vice president, safety, Pepper Construction Company.

Join our thriving community of 70,000+ superintendents and trade professionals on LinkedIn!

Join our thriving community of 70,000+ superintendents and trade professionals on LinkedIn! Search our job board for your next opportunity, or post an opening within your company.

Search our job board for your next opportunity, or post an opening within your company. Subscribe to our monthly

Construction Superintendent eNewsletter and stay current.

Subscribe to our monthly

Construction Superintendent eNewsletter and stay current.