Purdue University engineers and entomologists are making some sweet discoveries about how honeybees build and structure their honeycombs, which could lead to new fabrication techniques taken from the buzzing builders.

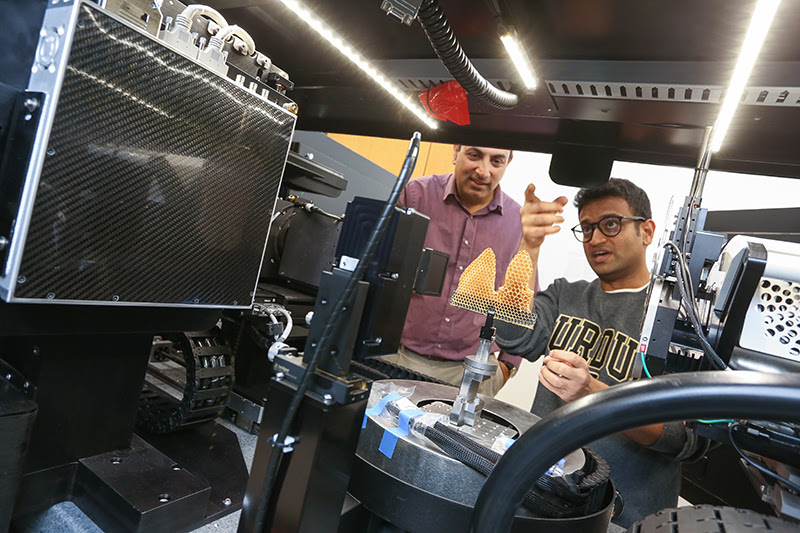

Purdue’s Ransburg Professor of Materials Engineering Nikhilesh Chawla is one of the first to utilize 4D imaging to delve further into the complexities of the honeycomb. The imaging allows a time-lapse view of the bees’ work without cutting into their home.

The innovative view of the bees’ construction found techniques that could eventually translate into new concepts for structural materials or additive manufacturing for the construction industry. Chawla said some of the junctions between the honeycomb cells were created using less material, with the resulting porous connections resembling Swiss cheese.

“It’s a lesson in materials utilization that could lend itself to new ideas and practices in structures,” Chawla said. “Their honeycombs are still perfectly fine. From that perspective, humans may not actually need as much material in some areas that are not quite as important from a structural point of view.”

Chawla’s work shows how humans can draw important lessons from the plant and animal world in a discipline called biomimicry, which investigates naturally occurring materials and behaviors and draws inspiration to design new products, systems and buildings. Chawla said there are aspects of honeycombs already used in several applications, from construction and structural materials to shoes.

Chawla said people don’t truly understand how bees make the honeycombs. For example, most theorize the honeycomb chambers start as cylinders and then are molded by the bees into the well-known hexagonal shape.

But a sophisticated 3D X-ray microscopy technique, combined with a time lapse, provided an unprecedented means of studying and quantifying the honeycomb’s microstructure.

The resulting 4D imaging showed chambers are built with panels. Research also found bees go to great lengths to strengthen the honeycomb structure by first creating a vertical spine for support, and then building the hexagon cells out horizontally.

“Over time, they continue to make the spine thicker because they understand there is more weight from the wax on it, and they need that backbone to be strong and rigid before they can add more and more of these cells growing outwardly,” Chawla said.

Chawla’s overall research focuses on 4D-materials science. The approach – called tomography – uses nondestructive X-rays to add time as a fourth dimension to 3D measurements and analyses. The 4D approach is important in examining structural evolution, including deformation and corrosion that take place over time.

Learning from honeybees is just the first step in the Purdue team’s biomimicry research. Successfully applying those lessons with tools like 3D printing is next. Chawla said there are plans to build honeycombs of different sizes, and even different shapes and evaluate their durability with compression tests.

In addition to honeybees, Chawla’s biomimicry research involves looking at the porous cellular structure of cacti and how fluids are moved up and down throughout the plant.

“It’s just a lot of fun to work with these kinds of natural materials because you just never know what you’re going to find,” he said.

The Purdue research team is made up of Chawla; Brock Harpur, assistant professor of entomology in the College of Agriculture; and Rahul Franklin, a graduate research assistant in materials engineering. Their work was published in the journal Advanced Materials.

Source: Nik Chawla, nikc@purdue.edu

Join our thriving community of 70,000+ superintendents and trade professionals on LinkedIn!

Join our thriving community of 70,000+ superintendents and trade professionals on LinkedIn! Search our job board for your next opportunity, or post an opening within your company.

Search our job board for your next opportunity, or post an opening within your company. Subscribe to our monthly

Construction Superintendent eNewsletter and stay current.

Subscribe to our monthly

Construction Superintendent eNewsletter and stay current.