6 ways superintendents can help prevent jobsite theft

6 ways superintendents can help prevent jobsite theft

By Janan Guillaume

Construction theft is a serious problem that negatively impacts jobsite productivity and profitability. Based on recent FBI data, statistics show that almost 12,000 construction site thefts occurred in 2022, with loss estimates ranging from $300 million to $1 billion annually. Unfortunately, most stolen items are never recovered. While difficult to quantify, the total impact of construction theft is even greater when the hidden costs are considered, including jobsite delays and work stoppages.

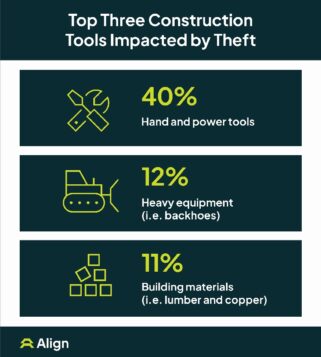

A study conducted by two East Tennessee State University professors and presented at the 2019 ACS International Congress found that the top three categories of stolen property were hand and power tools (approximately 40% of stolen items), heavy equipment like backhoes (12%) and building materials, including lumber and copper (11%). Beyond the proven methods for discouraging construction site theft — such as erecting physical barriers and other deterrents — how can superintendents better prevent jobsite theft?

Behind the scenes theft-prevention methods

Field-tested tactics for stopping construction theft include installing adequate lighting, having security guards or police patrol after hours when workers are not present, placing security fencing around the site perimeter, posting warning signs around the site perimeter and setting up a remote monitoring or surveillance system near site access points. While these methods make it harder for potential thieves to enter the jobsite or more difficult to steal assets, once they do so, the roles that internal processes and company culture play in theft prevention are often overlooked.

The following are six ways can help prevent jobsite theft beyond physical deterrents.

The following are six ways can help prevent jobsite theft beyond physical deterrents.

- Improve internal processes

Decrease asset theft and loss by improving the processes of receiving, tracking and storing the tools, equipment and materials used onsite. If these processes are suboptimized through inefficiencies or lax adherence to existing protocols, it can be difficult for your crew to know if theft, negligence or disorganization is to blame when assets go missing. Additionally, optimizing internal processes could prevent theft and make it easier to recover stolen items. - Develop, adhere to a comprehensive site security plan

Create a security plan and daily security checklist based on the specifics of your jobsite. Security plan elements may include a site map; details on where fencing, gates and locks will be located; whether electronic surveillance and security lighting will be used and, if so, where they will be placed; visitor check-in policies and procedures for securing tools, equipment and materials at night and on weekends. A plan alone does nothing — training workers and holding them accountable for following the plan is vital to success. - Maintain updated asset records

In case of a theft, it is crucial to have ready access to the serial numbers of power tools, heavy equipment and vehicles onsite documented for authorities to increase the chance of recovery. Often, the easiest way to track tool serial numbers is to tie them to the asset numbers used by your tool crib. For heavy equipment, document the unit’s year, make, model number and serial number. Consider registering your fleet with a national database like the National Equipment Register to help increase the chances of recovery if a theft does occur. - Conduct regular site inventories

It may sound obvious, but you must know what tools, materials and equipment are on your jobsite to know if an asset is missing. That means conducting a regular inventory of assets onsite. While it’s possible to conduct inventory using pen and paper, barcodes and RFID labels combined with scanners or mobile apps can make the inventory process less time consuming and labor intensive, especially on sprawling commercial sites. - Implement real-time asset tracking

Searching for and tracking assets in real-time using technologies like GPS, wireless BLE and barcode scanning allows you to know where assets are and how many you have on hand. This technology can help prevent theft or misuse by pinpointing the exact location of assets, ensuring equipment is not taken offsite, and preventing unauthorized usage. - Develop a strong company culture

A company culture that rewards continuous improvement is key to successfully implementing process improvements. Furthermore, cultivating transparency, accountability and collaboration between the tool crib, equipment yard, your jobsite and the office can help better track assets and limit loss. Spending the time to build a strong internal culture is your responsibility. Practical measures you can take to help achieve this goal include ensuring requisitioned tools and equipment are assigned to specific crew members, providing adequate security training to your crew and asking them for suggestions on how to continually make improvements to jobsite security.

With workforce shortages and rising material prices squeezing profit margins, contractors can’t afford to absorb the costs associated with construction theft and asset loss. By supplementing proven theft prevention methods with a focus on optimizing internal processes and cultivating a strong corporate culture, you can be part of the solution to reduce the downtime associated with missing tools, boost worker productivity and keep your projects on track.

Janan Guillaume is vice president of product at Align Technologies.

Join our thriving community of 70,000+ superintendents and trade professionals on LinkedIn!

Join our thriving community of 70,000+ superintendents and trade professionals on LinkedIn! Search our job board for your next opportunity, or post an opening within your company.

Search our job board for your next opportunity, or post an opening within your company. Subscribe to our monthly

Construction Superintendent eNewsletter and stay current.

Subscribe to our monthly

Construction Superintendent eNewsletter and stay current.