By Tom Rossi

Labor shortages. Escalating costs. Supply chain delays. The issues that once caught construction teams off guard are now part of the planning and preconstruction process. Companies have not only been forced to do more with less, but they have also had to do it without sacrificing cost or schedule — and the field is where many teams feel the biggest impacts. While navigating the continued challenges of lead times for materials requires a complex approach, it’s the simple principles — combined with technology — proving successful for project teams in today’s environment. The following are four tips Barton Malow employs to navigate these challenges.

1. Commit to transparency + clear communication

There’s no replacement for transparency, and our teams pair technology with tried-and-true processes in place to ensure open lines of communication between all parties, including the owners. Teams in the field hold regular weekly meetings with owners to keep them engaged and informed about the:

- Status of current project construction schedule

- Expected major equipment and material delivery dates

- Changes/shifts required to accommodate material delays that could impact the schedule

To complement weekly meetings, foremen and their teams also meet daily to discuss the plan of the day to review any changes in direction and tasks — keeping the team focused and safe with a clear plan before beginning each day.

Senior Electrical Estimator Steve Vallieres also stresses the importance of direct access to experts internally. “Providing the operations team with subject experts to reach out to help bridge the gap between the field and office teams. The boots on the ground don’t have time read through contracts, so streamlining internal communication also increases overall efficiency across the board,” he said.

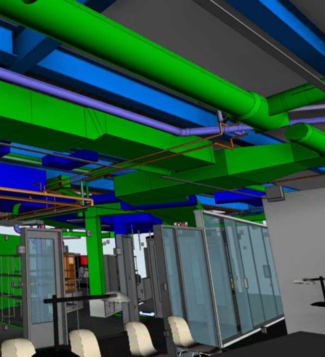

Collaboration up front, and use of BIM, allows team members to make decisions when it comes to phasing or to adjust for any unexpected changes in lead times. This model is available at the foreman’s workstation, so it’s always visible and allows for real-time planning. Just as anything else in the field, BIM is only successful when paired with effective communication. “BIM meetings need to be structured to maximize everyone’s time, while addressing and prioritizing issues. The team should focus on the latest issues and resolve them in the meeting or shortly afterward. Issues should not linger, and if one is difficult to resolve, I find it’s best to go walk the site to see it with my own eyes, discuss financially responsible options and then act to avoid losing more valuable time,” said Vallieres.

2. Allow for flexibility in specs

Many times, specs are written to specific manufacturers and equipment, which reduces opportunities to make adjustments and decisions based on lead times. Modifying specs to accept other manufacturers allows teams to order materials and equipment based on availability. Remaining rigid in specs can put schedule and budget at the mercy of one manufacturer and reduces creativity to meet project goals, but like all project decisions, the specs cannot happen in a silo and require clear, transparent communication.

While adjusting specs helps alleviate issues associated with delays in materials and shortage of labor, it’s vital that any flexibility or potential equipment restraints have been cleared by the client and the correct stakeholders. “Flexibility is one way to overcome long lead times, but it is crucial that we engage the owner early and truly understand why their specifications demand certain things before taking liberties and changing them,” said Vallieres. “Some specifications have been produced by the people who operate the facility, and making a change could cause interruptions for plant operations and maintenance. The way we leave the job is equally as important as completing it, so getting clearance and communicating with the correct people who will be using the building is imperative.”

3. Expand your network

In addition to remaining flexible in specs, opening your vendor network can have a big impact when it comes to dealing with long lead times, but just like the specs, it must be done responsibly and with owner sign-off. Every company has trusted vendors and preferred partners, but the fact is, we can’t control the market and materials. Opening the vendor network allows teams to start on long lead items and even procure equipment directly to cut down on scheduling.

Expanding your network also gives owners options when making critical decisions that have a direct impact on cost and schedule. To some owners, schedule is more important than cost, and they are willing to spend more to meet a timeline; expanding your network not only gives owners more choices, but it also offers new vendors an opportunity to prove what they can do — potentially leading to more business while helping teams further address lead time issues.

4. Anticipate changes in sequencing

Perhaps the biggest advantage of early planning, collaboration and communication is that teams know up front what will be late and can plan for those delays. Pulling ahead work that can be done, such as cable, pipe and ductwork, while waiting on longer lead-time items is one adjustment in sequencing that can have a positive impact on schedule. While setting equipment first is preferred, project teams are forced at times to work in the opposite direction, adjusting sequencing based on what is coming to keep work moving and prevent project delays. “Sometimes, setting the equipment first creates other challenges to disciplines scheduled later in the project. Being ahead of issues helps resolve these complex shifts in sequence, but pulling ahead work must be weighed against what makes the most financial sense, as changes could require higher paid trades to work overtime to bring the schedule back in line,” said Vallieres.

The top three issues affecting project teams today — and for the foreseeable future — are still lead times, equipment procurement and materials. Addressing them as critical points right out of the gate allows everyone involved to mitigate potential impacts to both schedule and budget, while also enabling creativity and innovation to overcome the challenges that come along with them.

Tom Rossi is senior estimating manager – MEP, Barton Malow Company.

Join our thriving community of 70,000+ superintendents and trade professionals on LinkedIn!

Join our thriving community of 70,000+ superintendents and trade professionals on LinkedIn! Search our job board for your next opportunity, or post an opening within your company.

Search our job board for your next opportunity, or post an opening within your company. Subscribe to our monthly

Construction Superintendent eNewsletter and stay current.

Subscribe to our monthly

Construction Superintendent eNewsletter and stay current.