By Thomas Taylor

Studies from the U.S. Environmental Protection Agency state that Americans spend 90 percent or more of their lives indoors1. This is one reason why the USGBC’s LEED 2009 rating system, which is being used by most project teams that have potential LEED-certified projects in the works, rewards teams from keeping harmful materials out of the facilities they build.

Almost all manufactured materials used on construction sites contain some amount of chemicals. The truth is, chemicals that emit harmful gasses into the air, a process that is known as off-gassing, can be found in all sorts of other common construction materials. Plywood is held together with glue; paint contains chemicals used as stabilizers and drying agents and the plastic used in conduit or pipe is petroleum-based.

These are materials we use every day and go into every building ever constructed, so many don’t understand the issue with using them in a LEED project. And, they may question why the guidelines are so different for a project seeking LEED certification. The reason the USGBC rewards teams for keeping these materials out of building projects is that some of the materials contain volatile organic compounds, or VOCs. These are considered to be harmful to some people, especially those who suffer from respiratory problems or are highly sensitive to chemicals.

The presence of odor can cause people to suspect they have been exposed to something that may be harmful to their health2. We have all been on a jobsite where someone is using paint, adhesive, sealer or something that emits a foul odor. You may have worked on a job or with a building material that made you feel lightheaded, made your eyes water or even made you sick to your stomach. Over the years, we have tried to protect ourselves and others working on the job from those conditions. We have gotten used to reading OSHA’s Material Safety Data Sheets for materials before we use them. However, the VOC content of an adhesive, sealant, paint or coating may not be listed on the MSDS. It is not that the manufacturer is trying to hide something; it is because the manufacturer is not required to print that information.

The LEED rating system uses the term “low-emitting” to identify the chemicals used in all different kinds of construction materials. It does not matter if the materials used have a strong odor or if it they have no smell at all; they could contain some level of VOCs. This is why it is important to remember to use only those materials that have been approved for your project.

In the event that the LEED rating system is being used to certify the design and construction of a building, the USGBC rewards teams for taking precautions to keep high amounts of VOCs out of the building.

There are four credits within the LEED rating system that specifically address indoor air quality as it pertains to low-emitting materials:

IEQc4.1 Low Emitting Materials – Adhesives and Sealants

This credit requires skilled-trade workers that work inside of the building to understand the importance of using the correct adhesives and sealants on the job. Every trade worker installing material inside of the building must use the proper adhesives and sealants. In order to comply with this LEED credit, each of these materials must contain no or very low levels of VOCs.

IEQc4.2 Low Emitting Materials – Paints and Coatings

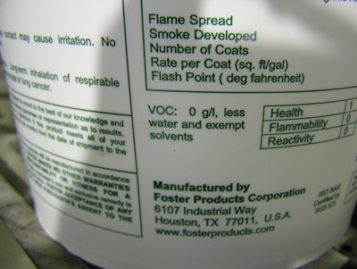

This credit requires any trade worker applying paint or a coating inside of the building to use only the proper, approved materials. To comply with this LEED credit, each paint or coating must contain no or very low levels of VOCs. The LEED rating system measures the VOC content in grams per liter, and each paint or coating must be below the stated threshold.

IEQc4.3: Low-Emitting Materials – Flooring Systems

This credit focuses specifically on any type of floor covering. If your work does not involve the installation of flooring materials, you do not have much to worry about with this credit. However, on any LEED project, it’s important to note that everyone involved in the project is responsible for the outcome of the project and needs to work together. The success of a project is not measured solely by the ability to finish the work; there is also a responsibility to assist in the LEED certification process. Any trade worker that installs flooring material inside of the building must use the proper, approved materials. To comply with this LEED credit, each flooring material must contain no or very low levels of VOCs.

IEQc4.4, Low-Emitting Materials – Composite Wood and Agrifiber Products

This LEED credit looks at a particular type of VOC found in many types of composite wood and agrifiber: urea-formaldehyde, which is a contributing factor to poor indoor air quality. To comply with IEQc4.4, each composite wood and agrifiber product used must contain no added urea-formaldehyde. Composite wood products include common plywood, wood trim, doors, blocking, counter tops and case work.

To help maximize the number of LEED credits earned when it comes to materials used in the project and on the jobsite, time should be dedicated to identifying all of the materials that might be used during construction in the early stages of a project. Each of these materials must be submitted for review and approval before they are purchased for the project. Each crew leader or foreman should be provided a list of all of the approved materials, in addition to their corresponding Material Safety Data Sheets, at the project site. Following these guidelines before construction begins will help lower the project cost and ensure a successful LEED project.

1The Inside Story: A Guide to Indoor Air Quality. U.S. EPA/Office of Air and Radiation. Office of Radiation and Indoor Air (6609J) Co-sponsored with the Consumer Product Safety Commission, EPA 402-K-93-007.

2Workplace Safety & Health Topics. Center for Disease Control and Prevention, http://www.cdc.gov/niosh/topics/indoorenv/ChemicalsOdors.html.

Thomas Taylor has 35-years of experience in the construction industry with an emphasis on sustainability. He is a principal and co-founder of sustainability consultancy firm Vertegy.

Join our thriving community of 70,000+ superintendents and trade professionals on LinkedIn!

Join our thriving community of 70,000+ superintendents and trade professionals on LinkedIn! Search our job board for your next opportunity, or post an opening within your company.

Search our job board for your next opportunity, or post an opening within your company. Subscribe to our monthly

Construction Superintendent eNewsletter and stay current.

Subscribe to our monthly

Construction Superintendent eNewsletter and stay current.