By Matthew Fitzgerald

Every construction professional has been there at some point in their career — subsurface utility unknowns causing injuries, schedule delays, budget concerns, design updates or unhappy customers. Plagued by inaccurate and unreliable utility records and as-builts, the design and construction industry continues to see the negative impacts of underground unknowns.

Imagine hitting a gas main next to a school or cutting off the oxygen to a hospital’s intensive care unit. What if a hidden set of trolley tracks suddenly derails your building schedule? Or you hit a decades-old fuel tank that was long forgotten until you find it right in the middle of your jobsite?

It happens. In fact, it’s common. We find issues every single time we create a map of what’s underground at a construction site. And yet, in our experience, about 90% of all construction projects don’t include comprehensive subsurface mapping before excavation.

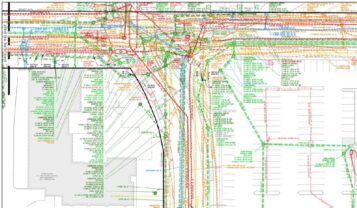

In failing to accurately locate subsurface utilities, owners, contractors and facility operations are at risk. The financial impact alone can be substantial as underground unknowns typically lead to an 18% change-order rate on complex civil site project contracts. By using complete, accurate, color-coded and extremely detailed maps and models, subsurface mapping creates a full picture of what may be lurking underground.

Where is the value?

According to the Purdue University Department of Building Construction Management — for every $1 spent on mapping at this level of detail, owners can save an average of $4.62 in cost avoidance for their project. Beyond the potential cost savings of finding an issue after a project has begun, having the knowledge of what lies beneath pays in dividends. Benefits include:

- Safety. Recognize greater safety measures as project teams implement and communicate the investigation results to those directly involved in the construction

- Budget. Provide cost-certainty earlier during design and preconstruction phases, as mapping results give clearer vision for civil operations

- Design. Provide greater confidence in civil design aspects such as proposed utility routing and profiles, site grading, existing utility shut-offs, utility tie-ins, foundation locations and building layouts

- Schedule. Give greater clarity on real durations for civil construction operations due to increased accuracy of overall civil design, allowing owner to plan and communicate more effectively with campus members

- Operations. Protect the customer experience for a passenger, student, patient or tenant based on greater confidence and planning of surrounding construction operations

Subsurface utility mapping is most valuable when considering a new project with these attributes:

- An operating campus

- An aging campus with decades of compounded infrastructure

- Dense urban areas with complicated sitework

- When building adjacent to high-risk utilities such as oxygen or gas

However, it is being made clear that any project can utilize a SUM-customized approach that properly addresses the underground risk present. One project may need detailed sewer reports, while the next needs surface features only. One project may need detailed conduit information and butterfly diagrams, while the next is only concerned with horizontal alignments. One project wants to coordinate their site logistics in three dimensions, while the next prefers two dimensional. The question is not whether a project needs SUM, but rather the approach that best meets the needs for the construction team, the client and the budget.

Synergistic technologies

Some owners might turn to a private utility locating company to mark underground lines. The fact is that private locating companies typically don’t dig deeply enough — both literally and figuratively — to identify all the dangers to projects and workers.

Unfortunately, there is not one utility-locating technology that yields accurate results for all encountered utilities. To effectively mitigate the risk facing a project, while knowing and clearly communicating the limitations of certain equipment, utility designators require several different surface-level technologies. McCarthy utilizes the following technologies to designate existing utilities:

- Electromagnetic utility locators — used as our primary method for locating utilities. This technology allows us to hook directly to the utility and provides location, GPS tracking and approximate depths.

- Ground penetrating radar — the Stream C is used for a compact array solution, generating real time 3D mapping of underground utilities. This technology has 34 antennas in two polarizations and can produce GIS-based digital maps when exported. Also, MALA technology is utilized for sites of all sizes to investigate voids, buried structures and other underground utilities.

- 3D printing — allows our team to create models of existing infrastructure to implement into 3D models of proposed buildings throughout a campus. This process gives invaluable viewpoints into a proposed project’s area of influence and possible areas of concern.

- Laser scanning — used to aid in the 3D modeling of certain areas of a campus or internal building. The gathered point cloud is used to determine exact dimensions for critical areas of a project’s design and construction.

- Colorized LiDar scanning — is typically flown with a drone and provides high-density colorized point clouds that can be seamlessly merged with our 3D model of existing utilities.

- CCTV truck video cameras — are used to capture video footage and condition assessment reports for pipes of all sizes. The truck also has a lateral launch capability, allowing our team to view and inspect building lateral connections.

- Concrete scanning — allows us to locate items below concrete slabs such as conduits, rebar, PT Cables, pipes, etc. This tool can have multiple applications, especially in the renovation setting or during the preconstruction phase of a job.

- Infrared energy pattern analysis — can be used manually or mounted to a drone or plane. It uses sensors to determine drastic changes of temperature, which shows locations and alignments of utilities such as chilled water and steam.

- Acoustic pipe locator — sends and receives waves throughout the soil and exports data for objects found below the surface. The technology proves to be valuable in situations with plastic material with no tracer wire.

- Drones — are used for project inspections, high-definition photos, LiDar scanning, site topography and infrared scanning.

- 360 degree reality capture — is used to provide 360 degree site walks throughout an area, as well as side-by-side views between the real world and 3D model at any desired location.

Implementing these technologies impacts early planning, design, construction and facilities management operations — and budgeting and planning become more accurate and reliable. This can all be attributed to a single source of truth surrounding existing utility data.

Matthew Fitzgerald is a registered professional engineer and senior business development manager for McCarthy Building Companies.

Join our thriving community of 70,000+ superintendents and trade professionals on LinkedIn!

Join our thriving community of 70,000+ superintendents and trade professionals on LinkedIn! Search our job board for your next opportunity, or post an opening within your company.

Search our job board for your next opportunity, or post an opening within your company. Subscribe to our monthly

Construction Superintendent eNewsletter and stay current.

Subscribe to our monthly

Construction Superintendent eNewsletter and stay current.